|

Agie EDM Agie EDM |

|

|

Agie® Mondo Star™ 50 CNC Electrical Discharge Machine (EDM)

-

Made in USA.

-

60 amp peak amps.

-

Automatic 25 position electrode changer for full unattended operation.

-

Erowa Swiss-made tooling system with accuracy and repeatability of .00008" (.002mm).

-

Offsite remote monitoring with video viewing of machining operations.

-

Orbit in any real or imaginary plane.

|

|

|

How this machine benefits you, our valued customer:

-

Reduced

mold delivery times.

-

Increased

consistency between cavities.

-

Increased

flexibility in mold design and construction.

-

Increased

repeatability if modifications are needed after the mold

is built.

|

|

|

The Manufacturer

The Agie® Mondo Star™ 50 is manufactured in Davidson, North Carolina by the AGIE CHARMILLES group.

In 1988, the Swiss company Agie purchased the ELOX Company located in Davidson, North Carolina. ELOX was the largest American manufacturer of EDM machines.

In 1996 Agie was integrated under the AGIE CHARMILLES company into the Georg Fischer Manufacturing Technology group. |

|

|

The

Machine

Our Agie® Elox® Mondo Star™ has a large work tank which allows us to machine parts 27 x 36" and up to 1,100 lbs.

The full computer control allows machining or erosion in any direction; down, up, sideways, or at any 2-D or 3-D vector and will orbit in any real or imaginary plane.

Up to 25 electrodes can be loaded into the automatic electrode changer. When the program calls for the next electrode, an arm automatically changes the electrode and the program continues.

This allows for true lights-out, unmanned 2nd shift, 3rd shift, and weekend operation. Think about this: there are 63 hours between 5:00 p.m. Friday and 8:00 a.m. Monday. Imagine what this can do to delivery times. |

|

|

The

Tooling System

We use the standardized Erowa tooling system in the manufacture and use of our electrodes.

This Swiss-made interchangeable system is used whether we are grinding the electrodes, machining them in our vertical machining center, or loading them into our EDM.

No matter which machine the electrode is currently in, the Erowa system maintains accuracy and repeatability of .00008" (.002mm).

|

|

|

The

FUTURA V control

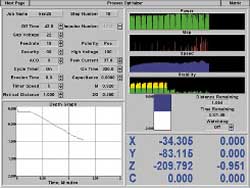

The Agie® Mondo Star™ has a completely revolutionary control system called FUTURA V, which is designed around the popularity of computer windows.

It is the only Windows-based control in the EDM industry with point and click mouse technology for programming.

The FUTURA V control has a flexible graphical interface designed to simplify complex jobs such as multi-cavity, planetary, helical shape and deep rib erosion.

The color monitor allows 3D simulation of the workpiece as well as of the machining sequence.

With its use of highly advanced artificial intelligence, AGIE’s unique and powerful adaptive current control combined with color diagrams show current data about erosion conditions.

It also allows real-time monitoring and optimization for high metal removal rates and production of accurate, distortion-free cavities that are totally repeatable. |

|

|

The

StarView remote monitoring

Our Agie® Mondo™ Star also has StarView, a revolutionary remote monitoring system that allows real-time images of the Mondo Star’s machining process to be viewed from a remote location such as an operator’s residence. The system uses a 2-inch digital ball camera to capture images of the Mondo Star in action.

After dialing up the network by way of a modem, the operator can view real-time video of the work in process, review the erosion process, access job screens, or check the Mondo Star’s operational status.

When accessing the job screens through StarView, workpiece layouts, data for the electrode or workpiece, and parameters and strategies can be seen for the job.

Should the remote viewer discover a discrepancy in the machining process or setup, the machine can be turned off from the remote location.

|

|

BACK TO TOP

Technical

information and pictures provided as a courtesy of Agie Ltd.

|

|

|

Copyright Integrity Mold, LP

2005 - 2010 |

Integrity Mold, LP • 3200 Curtis Drive, Suite 130, Fort Worth, TX 76116 • Tel: (817) 244-6677 • Fax:

(817) 244-6678 • data@integritymold.com |

|

|

|